Very productive weekend except for the shitty weather which made half of saturday and most of sunday a bust. the rest of the week looks pretty crappy as well. Hopefully it’s not going to prevent me from doing the rest of my list.

Where I left off was the console lid. After the epoxy had cured it was pretty solid. I’m curious to see how long this holds.

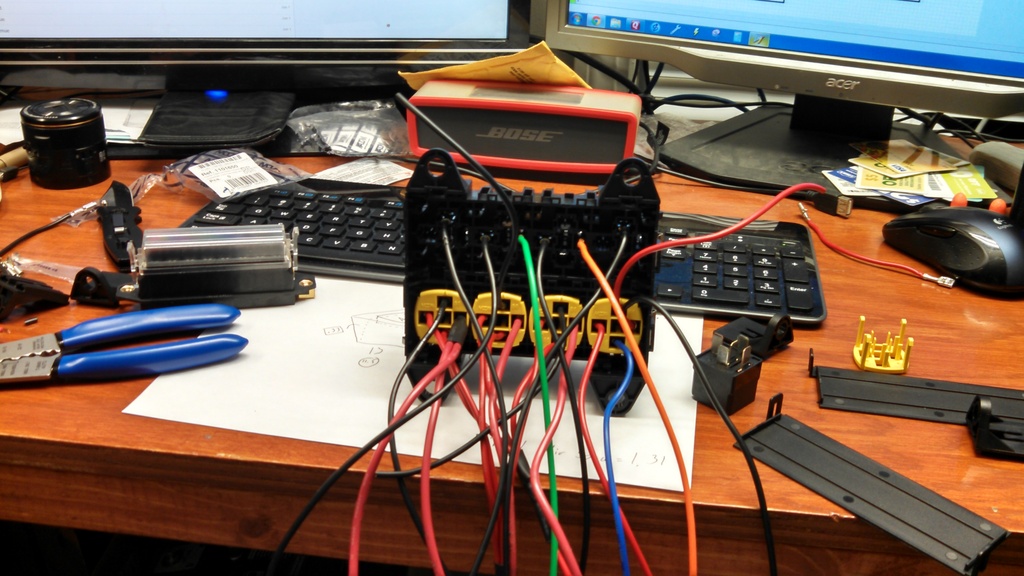

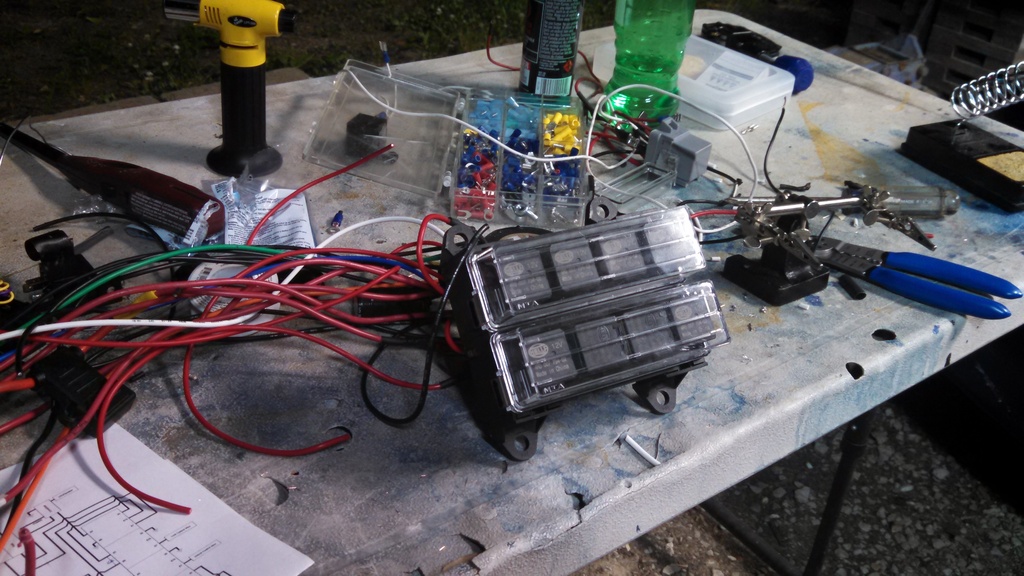

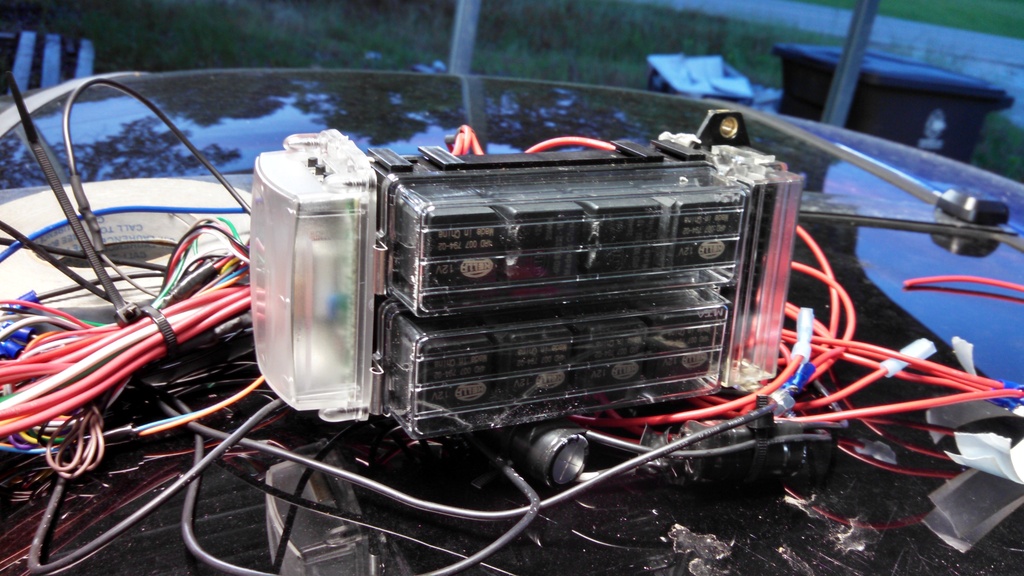

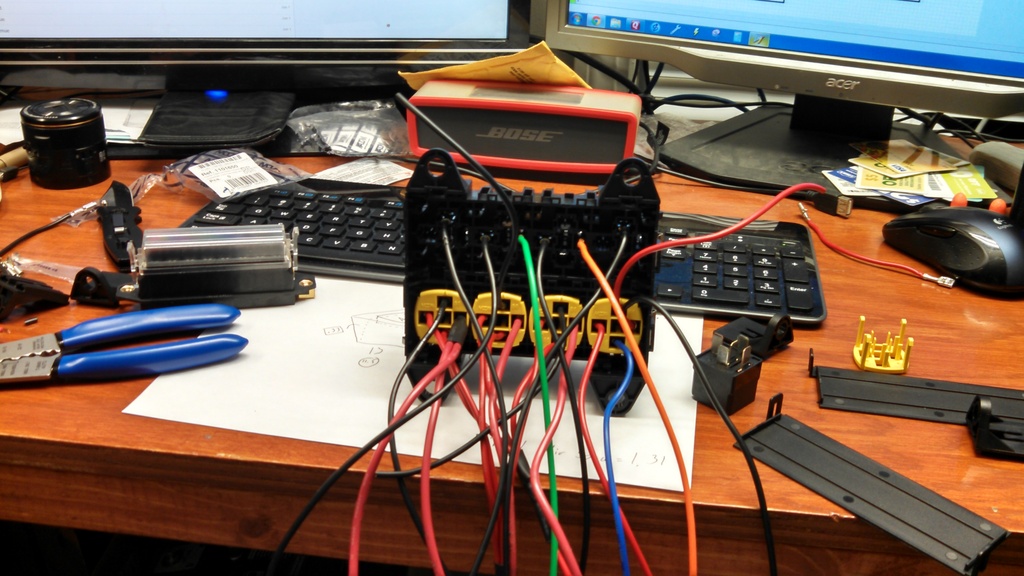

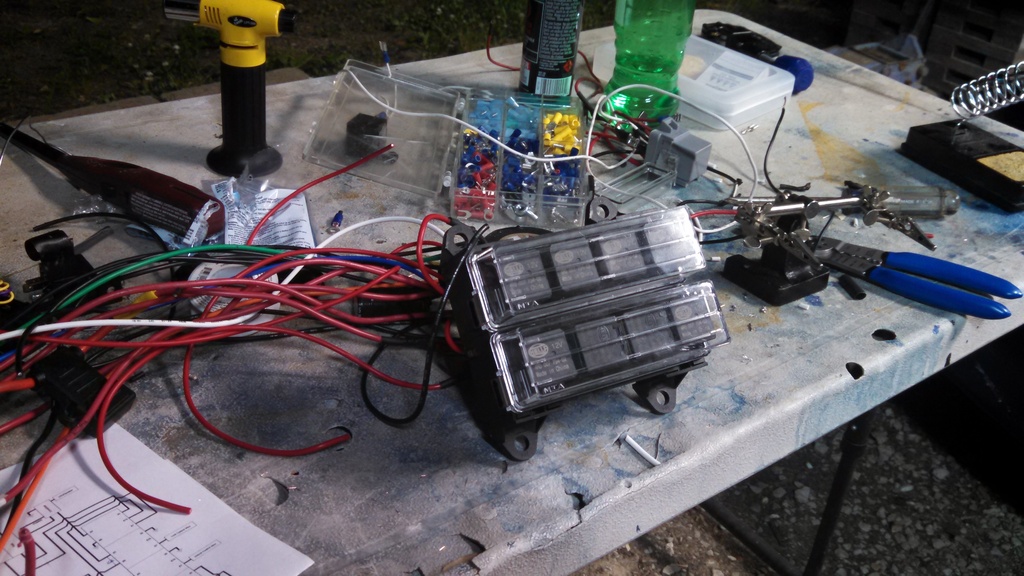

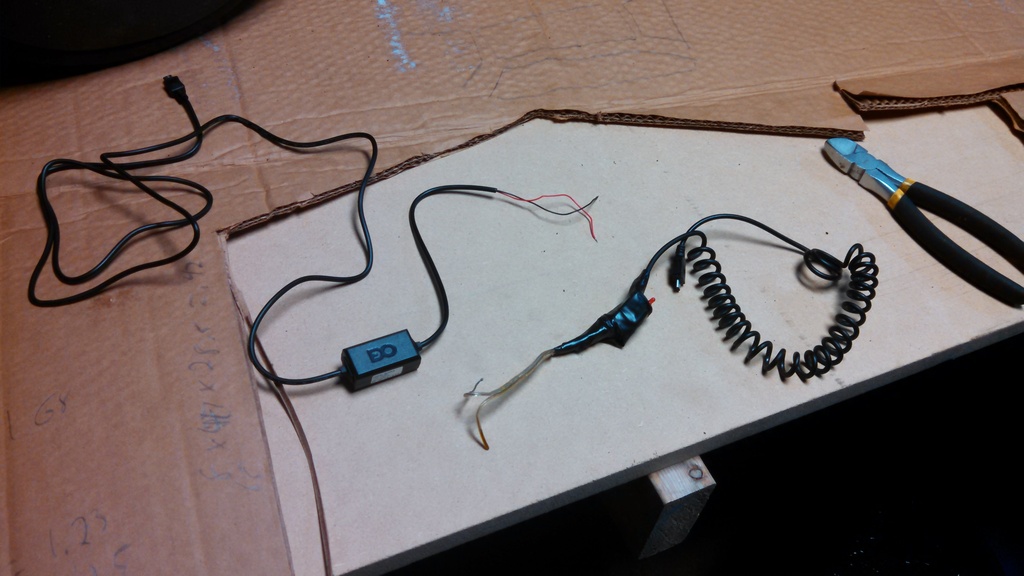

I began the time consuming process of wiring.

Hiding this turns out to be a little difficult.

I haven’t wired the fuses panel in with it yet

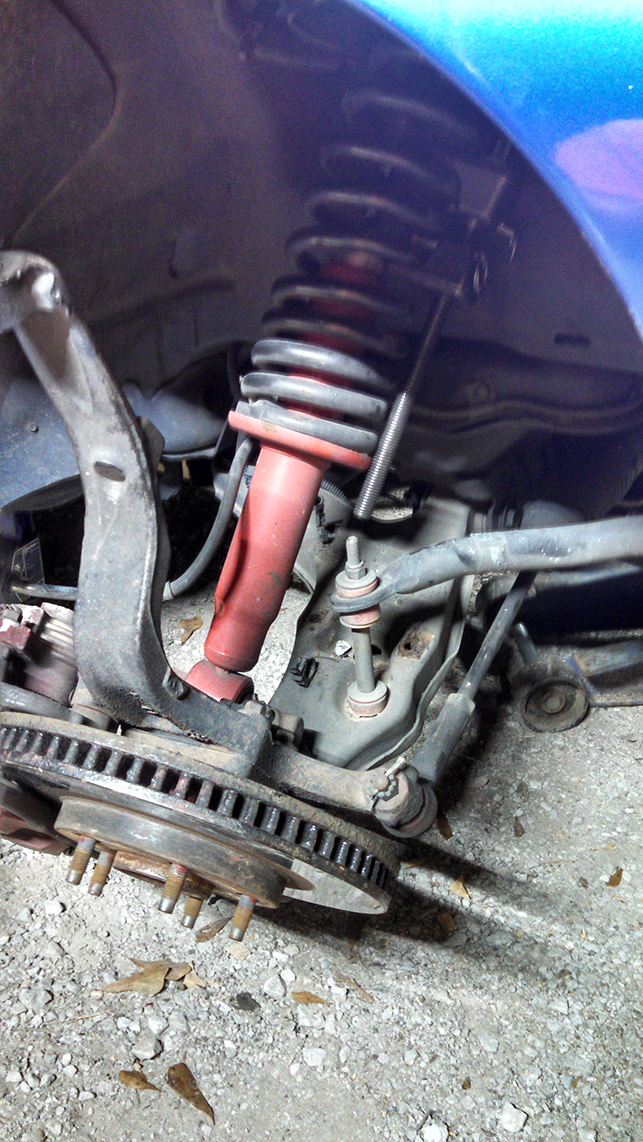

I took a swing in the dark as to my fuel pressure problem. The pump that Matt and I installed, whilst I was stranded in AL, came with a factory like hose.

I didn’t start to leak down until a month or so after I got back and drove it daily.

I decided to swap back to a rubber hose instead. Oddly enough we swapped it and it still wouldn’t hold pressure. That is until I marked it off the list. Then it magically held. It was quite annoying. In any case the pressure holds now when the car is off. Which means my push button start doesn’t require me to cycle the button to prime the fuel lines anymore.

This is an unusual problem that some people with cams and a low idle might be interested in.

(Edit: the following information is related to amp draw. The alternator actual cuts the charging off when The idle dips below 500 or so. I’ve got more information about that in a later post)

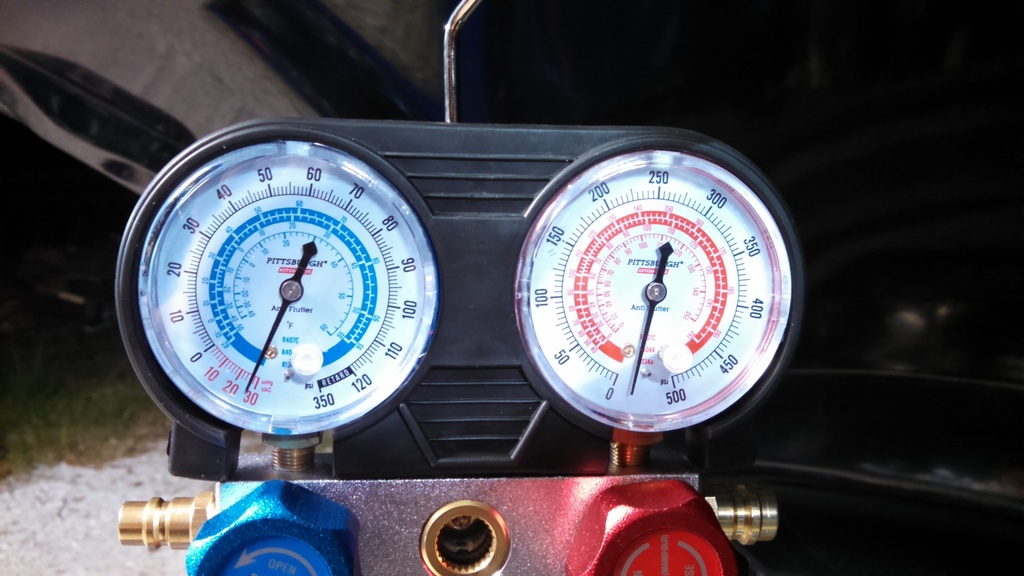

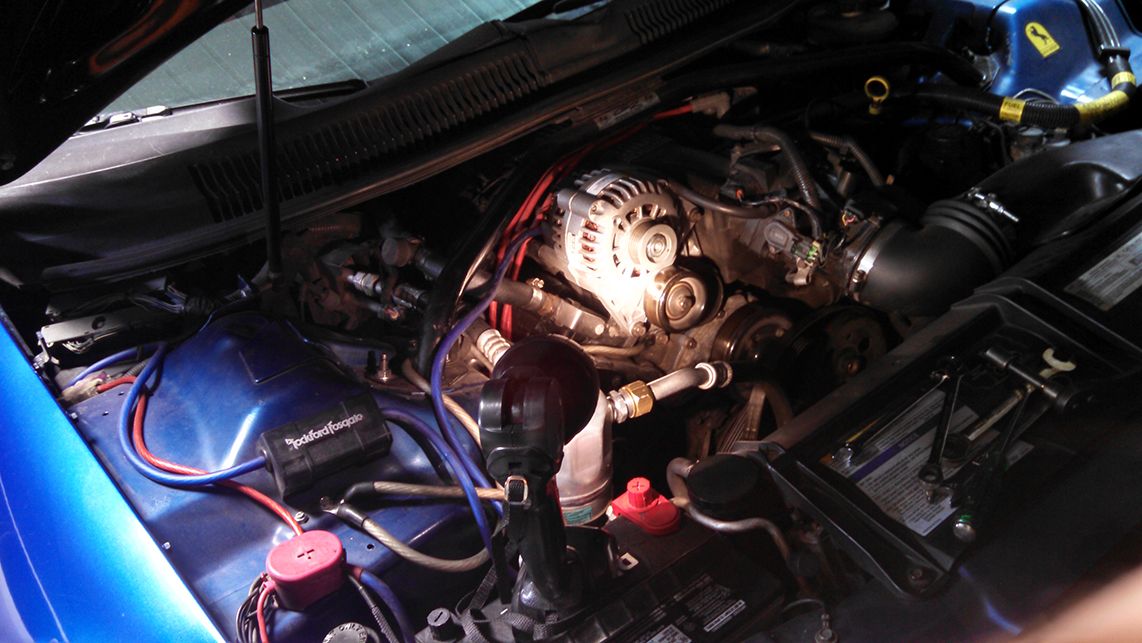

I have a problem where my ac is going and my blower is full blast and my voltage, when I come to a stop, drops due to all the power draw. My idle is set at 700 which is 50 below factory. So as my cam lopes it can hit anything from 650 to 750 rpm. Factory alternators are designed for 750 rpm. Which if rev the throttle slightly the voltage will go normal.

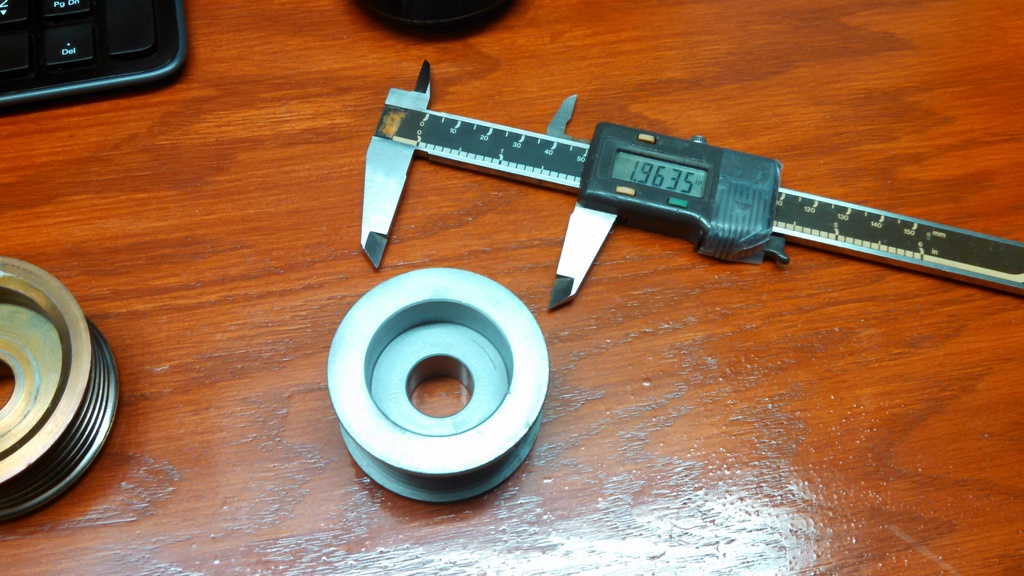

My solution or attempt at a solution is a new pulley for the alt. I got one that is slightly smaller diameter.

The gold pulley is a factory diameter

Factory circumference = 7.54

New Circumference = 7.00

New rev ratio vs factory = 108%

(Edit: This isn’t exactly the way you should calculate the RPM of the alternator. Pro tip: do it the right way)

So at 650 rpm the new pulley will simulate the engine running at 700 rpm. This may not be enough but it will help for sure. And I lower the idle to 675 hopefully as well.

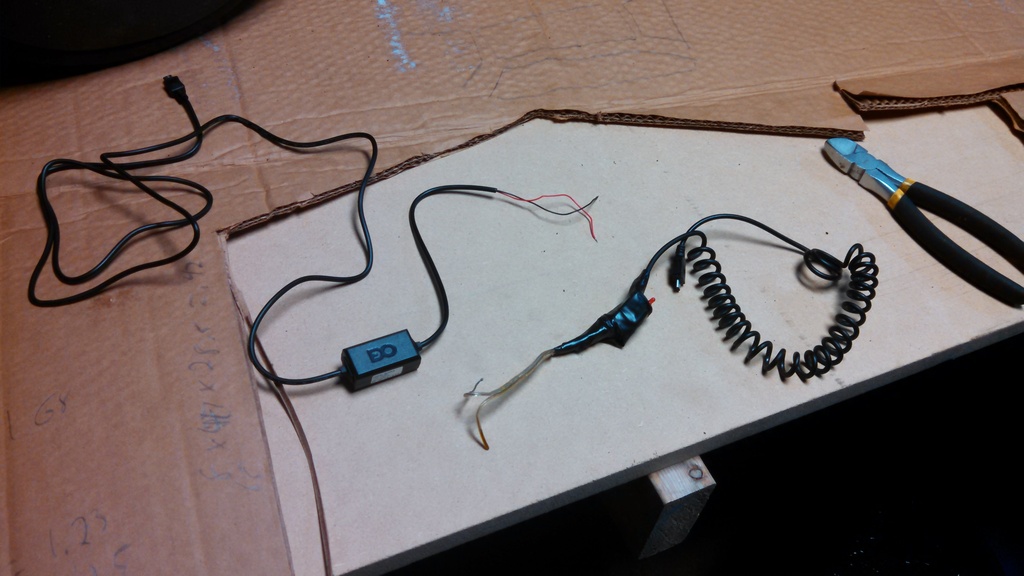

I swapped the phone dock charger from a chopped up plug in charger to a better 1.2A wired charger made for bikes and such. Hopefully my phone will charge and run nav at the same time. The nav seems to drain a lot of juice and the old charger barely keeps up.

it fits nicely.

The following is probably the best cosmetic improvement.

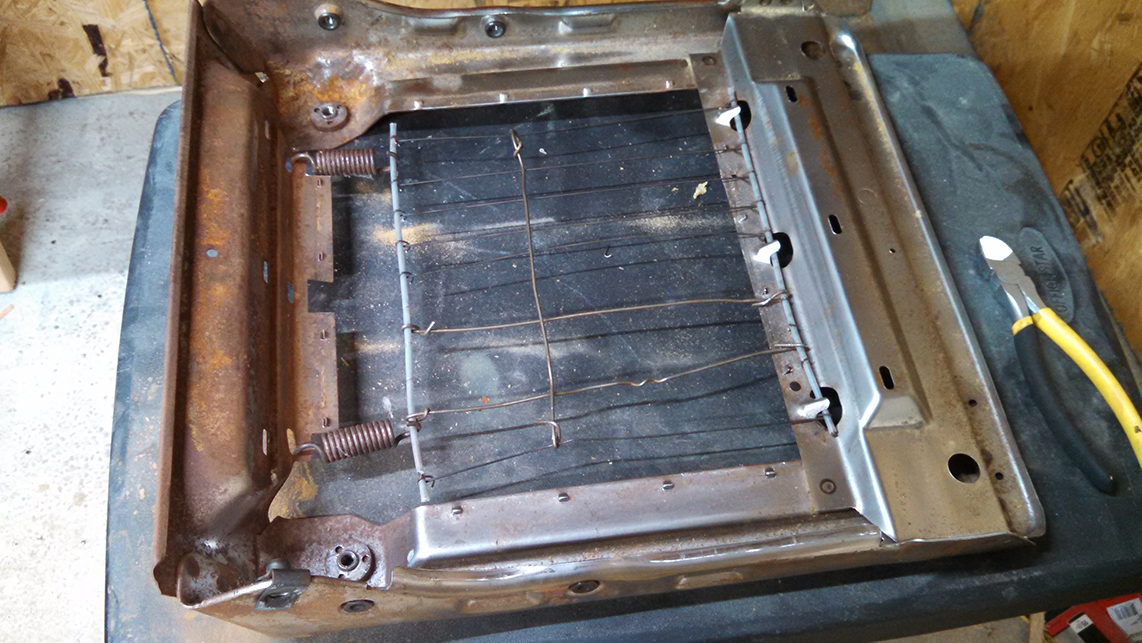

Headliner:

I managed to find a decent headliner at the pull a part with Laura and Jeff. It needed to be recovered but the headliner itself was in good enough condition to use.

Scrubbed off the old foam:

The rain started to pour so I threw it into the hatch for safe keeping.

I managed to install it after the rain stopped. it’s been a very long time since I had a headliner. The material came from WLS headliners. The graphite color is pretty dead on for the graphite interiors.